Evaluating Piano Keyboards for Rebuilders

As a rebuilder, when you quote a job, or as you start a job, you may wonder how the piano will play when the job is finished. Will the touch be too heavy? Will the customer be happy? We recommend you carefully check the keyboard condition and key ratio to assure best results. Your piano may very well work fine with the current keyboard, or a new keyboard may be beneficial. With the tools we give below you can be confident in the result.

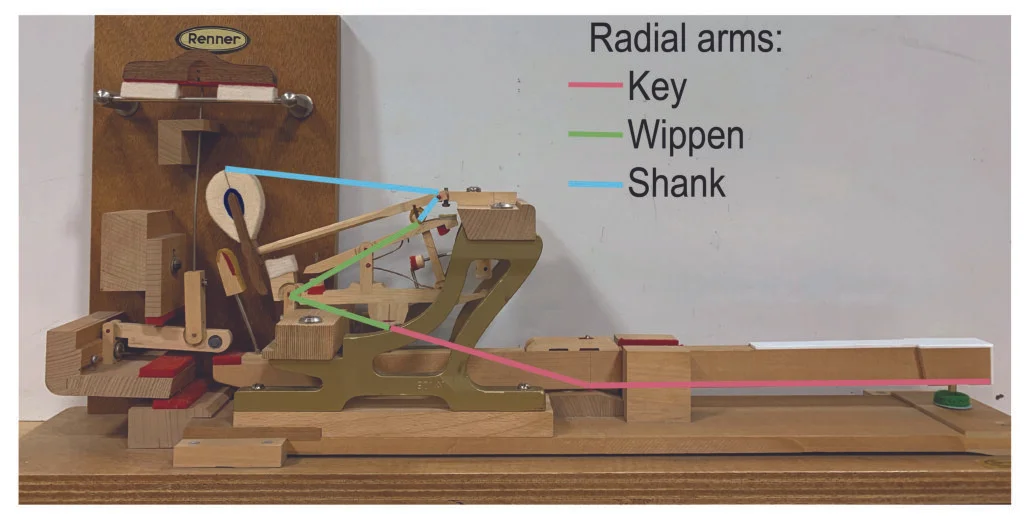

Radial arms used for calculating action ratio.

For a complete analysis we recommend calculating the action ratio or “AR” which involves taking a few easy measurements of the key, wippen and hammer shank. As part of building a new keyset, RPW calculates and simulates the action ratio with actual parts to ensure a successful action rebuild.

As a FREE service for piano technicians and rebuilders, we will calculate your key and action ratio for you, and provide analysis with recommendations for improvement. To send us data, please use this web form:

www.reyburn.com/geometry This web form includes a link to easy instructions with lots of pictures!

Calculating the key ratio and action ratio is just part of our process for designing your new keyboard. Here are just a few of the checks we run; the “magic line” or half strike capstan/wippen friction, action spread, stack position, jack function, hammer bore, and balance rail magic line, and more. Some issues we fix during our design phase automatically. Other issues such as stack position, we work with you the customer to ensure an optimal new keyset and action rebuild.

Piano keyboards last a long time, even in concert/performance instruments. However, long term and/or heavy playing, multiple action rebuilds, improper repairs, age and other factors can cause the valuable instrument you care for to need a new keyboard and action.

Common keyboard issues:

1. Key ratio problems. Many older and middle aged pianos have key ratio which is too high for modern parts. (See directions below to calculate your keyboard’s key ratio.)

To work effectively with modern high performance 17 mm hammers, most pianos need a key ratio between 0.48 and 0.52. Many older Steinway pianos have a key ratio of 0.54 or higher. With modern parts installed, pianos with a high key ratio will be too heavy to weigh off correctly.

2. Pulley or chucking keys. When the key can move forwards and back due to the balance rail hole being out-of-round, the pianist feels an uncomfortable loss of control and action efficiency is lost.

3. Worn out keys from over playing or multiple/poor quality keytop replacements (see picture 5 below). The width of the white keys, especially in the midrange can end up too narrow. If your keys are narrower than about 0.870 inches or 22.0mm, or the variation between adjacent keys is more than about .040 inches or 1.0 mm, the keyboard not only looks worn and poor quality, it’s uncomfortable to play.

4. Poor quality keyboard and action repairs or modifications. Let’s face it, not all piano service people are highly skilled, and occasionally improper repairs are attempted, sometimes causing issues that can’t be easily resolved.

5. Age and wood failure. Pianos in long term poor humidity conditions, water damage, or keyboards which are more than about 100 years old are often in need of replacement due to wood failure or delamination of joints.

Measuring the Linear Key Ratio:

You will need:

- An accurate tape measure (at least 1.0mm or 1/16th of an inch resolution)

- A sharp pencil

- A square/right angle tool

- A piano key. For simplicity, select a straight (no dog leg) natural (white) key at either end of the midrange. For instance key 21 or 51 on a Steinway B.

Take all measurements with the key upside down, out of the piano.

A. The Front (F) length is measured from the front of the white key material to the center of the balance rail hole at the underside of the key (pictures 1 and 2).

B. Determine the lift point of the capstan. Draw a line on the key perpendicular to the key bottom which intersects the point the capstan lifts the repetition cushion (picture 3).

C. Measure the Capstan distance from the front of the white key material to the capstan lift line on the key. Call this number “C”. (picture 4).

D. The Rear length (R or balance hole to capstan) is determined by subtracting F from C:

R = C – F

E. The Key ratio (K) is determined by this formula:

K = R / F

F. The Key ratio should be in the vicinity of 0.50, but anything between 0.47 and 0.60 is not uncommon.

Conclusions: Larger pianos such as Steinway B or D usually work best with key ratios of 0.50 to 0.52. Smaller pianos usually work well with 0.48 to 0.50. If the key ratio is outside the normal range, a new keyboard will enhance the piano’s value and playability immensely.

Notes:

If the capstan is not perpendicular to the key, use the center the lift point where the capstan contacts the repetition cloth. Ignore both the capstan angle and where the capstan enters the key. For angled capstans you should draw the lift point line at 90 degrees to the bottom of the key.

If the capstan is 90 degrees to the key, just measure to the capstan center (or capstan hole on key bottom).

If the repetition cloth is extremely worn, or you will be replacing repetitions during rebuild, measure using the repaired or new repetitions.

The “linear” key ratio measurement method presented above is recommended since it is the most direct and simplest to use. However there are are other valid methods for measuring and expressing key ratio which will give a different number, always higher. For instance we use the “radial arm” key ratio in order to calculate the action ratio, measuring diagonally from the bottom of the balance pin to the top of the capstan for key output. If you measure, then express or compare key ratios, please make sure the same measurement method is used for both results being compared, otherwise the comparison is meaningless since you’re comparing apples and oranges.

FOR MORE INFORMATION ABOUT OUR CUSTOM RETROFIT PIANO KEYBOARDS, PLEASE CONTACT REYBURN PIANOWORKS BY CLICKING HERE.

(In the example below the Key ratio is .53)